We’ve been innovating from day one. It’s an essential part of our culture.

We innovate for our customers, to help them become more efficient, more sustainable and to help them stay ahead of their competition. For example, we were the first to develop circular economies for the hi-tech aerospace metals we specialize in.

And we innovate for ourselves, to help us do more for less, reduce our carbon footprint and ensure the best possible safety for our team.

We find solutions, often before they’re needed

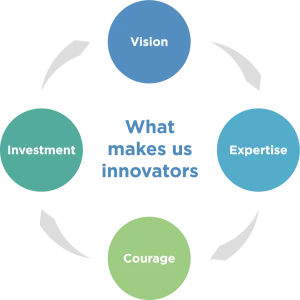

Innovation doesn’t just happen. It takes extraordinary vision, expertise, courage and investment to bring about change.

Because we understand the hi-tech metals our customers depend on, and because we’re brave enough to try something new, innovation is behind everything we do.

Take our titanium washline, the first of its kind. We developed it in direct response to our customers’ needs. Using pre-treatment with custom-made chemicals and a selection of magnetic, gravimetric and carbon sampling, we can process specialist titanium materials to aviation-grade standard.

We’re your R&D partners

The breadth and depth of expertise in our team means we have the insight to think about things differently. And because we have courage, we’re prepared to take risks and develop new technologies. This gives our customers the confidence to come to us with problems and involve us when they’re developing new materials.

We then collaborate with manufacturers and melters to develop the technology we need to process the next generation of titanium and superalloys.

‘Innovation is not in the piece of machinery; it’s in the people.’

Ruaraidh Williamson, CEO, IMET Alloys